Magnetostrictive Energy Harvester Development

| Links: Link

The project consisted of the design, simulation, construction and characterization of a vibrant magnetic structure for its potential use as the core of magnetostrictive vibrational energy harvesters. This element transfers the vibrations from an environmental source to the active magnetostrictive material, enabling this way the energy generation through the experienced magnetization changes and Faraday’s law principles. This way, its performance becomes essential in the harvester device energy conversion efficiency.

The first part of the project consisted of several numerical FEM simulations (by using MATLAB and Gmsh) to verify the viability of the design and optimize the system. This task was done by the modification of relevant parameters to reduce the resonance frequency and maximize the stresses generated in the active material for obtaining the maximum output power. The reduction of the working frequency is justified since most of the industrial processes take place at frequencies around or even lower than 100 Hz. At this interval, the piezoelectric harvester devices, which are the most commonly used, present relevant disadvantages related to their increasing size as frequency decreases. In this context, a compact, simple, long lasting and cheap structure design could improve vibrational energy harvesting performance in industrial applications thank to the substitution of piezoelectric harvesters by magnetostrictive ones.

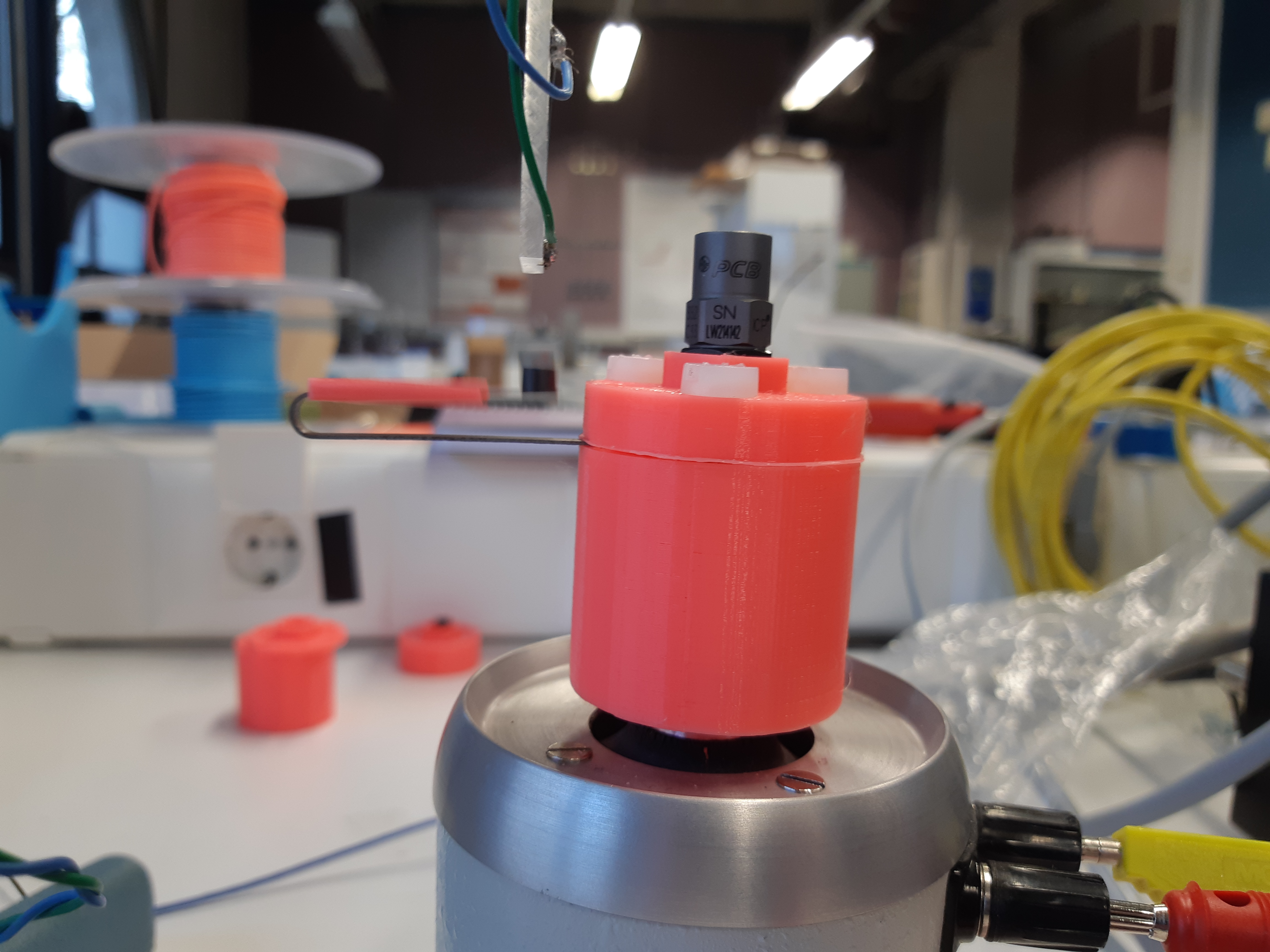

In the second part of the project a prototype was built in the laboratory and it was characterized to verify if the experimental results agreed with the numerical simulations and if satisfactory performance was obtained in terms of resonance frequency and amplitude of vibration.